Model Engineers' Workshop is the ideal workshop companion for all hobby engineers. Model Engineers' Workshop shines a spotlight on the tools and techniques used by model makers, light engineers, restorers and customisers and those who like making and modding their own tools. You'll find readers' tips, reviews of workshop equipment as well as articles on restoring old tools and making your own as well as the latest new technologies, techniques and materials. Model Engineers' Workshop magazine publishes 12 great issues a year.

Model Engineers’ Workshop

On the Editor's Bench

Extending the versatility of a ‘Parrot Vice’ • R. Finch adds some extras to his ‘universal’ vice.

Readers’ Tips

Six By Four Metal Cutting Band Saw Modifications • Robert Walker purchased one of the ubiquitous Chinese 6 x 4” metal cutting band saws, and soon set about making a number of modifications to improve its usability.

On the Wire NEWS from the World of Hobby Engineering

A Compound Slide for a Sherline lathe • Geoff Walker describes how he made a robust slide for taper turning on his Sherline lathe.

Modifications to a Cross Vice • Many years ago Laurie Leonard decided that the accuracy of drilled holes using a pillar drill could be better with more flexible workholding. He purchased a budget cross vice that could be bolted to the pillar drill table but found that there was room to improve its performance.

Artful Dodge #2 Always have a plan • Essential reading for beginners and valuable to old hands, this series by the late John Smith shares some of his wealth of skill and experience from over half a century in hobby engineering.

A Different Angle on Taper Turning • Ball centres provide a simple and effective way to support the work when turning tapers in the lathe. In this article Howard Lewis explains his approach to making various sizes of ball centre.

Workshop Photography Part 1 • We can't all be professional photographers or even access the most sophisticated of photographic equipment, but there are many simple things we can do to improve the quality of our workshop images.

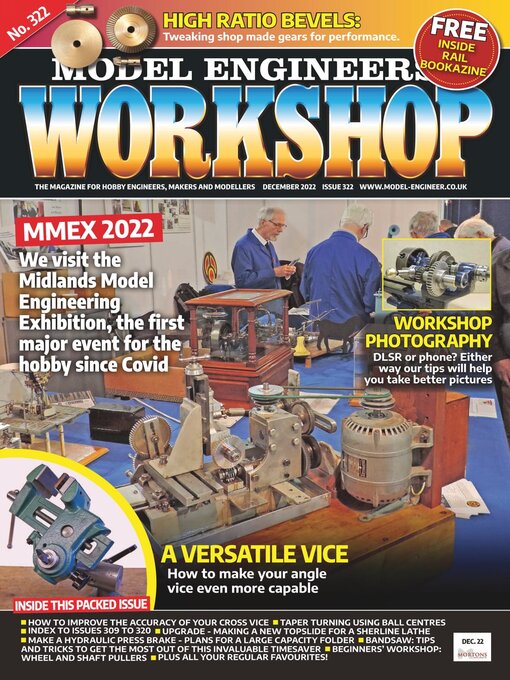

The Midlands Model Engineering Exhibition • October 2022 finally saw the return of a large scale model and hobby engineering exhibition after two long years of covid lockdowns and cancellations. Editor Neil Wyatt went along on the Friday to seek out interesting examples of workshop tooling.

Scribe a line YOUR CHANCE TO TALK TO US! • Readers! We want to hear from you! Drop us a line sharing your advice, questions or opinions. Why not send us a picture of your latest workshop creation, or that strange tool you found in a boot sale? Email your contributions to meweditor@mortons.co.uk.

Wheel and shaft pullers

Make a Hydraulic Press Brake • Paul Lousick needed a sheet metal press to make parts for an engine, he found the most practical solution was this sprung press brake that fits inside a 20-tonne press.

High Ratio Bevels • Bob Reeve continues the development work documented in “Bobs Better Bevels” (Ref 1). The bevel gears in question are the sort of bevels made by Model Engineers and are usually known as parallel bevels because the tooth depth is constant along the length of the tooth, unlike commercial bevels which are usually described as fully formed.

A Speedy Milling and Drilling Lathe Fixture • Paul Tiney describes a project suitable for beginners who ‘want to make something useful’.

May 01 2025

May 01 2025

Apr 01 2025

Apr 01 2025

Mar 01 2025

Mar 01 2025

Feb 01 2025

Feb 01 2025

Jan 01 2025

Jan 01 2025

Dec 01 2024

Dec 01 2024

Nov 01 2024

Nov 01 2024

Oct 01 2024

Oct 01 2024

Sep 01 2024

Sep 01 2024

Aug 01 2024

Aug 01 2024

Jul 01 2024

Jul 01 2024

Jun 01 2024

Jun 01 2024

May 01 2024

May 01 2024

Apr 01 2024

Apr 01 2024

Mar 01 2024

Mar 01 2024

Feb 01 2024

Feb 01 2024

Jan 01 2024

Jan 01 2024

Dec 01 2023

Dec 01 2023

Nov 01 2023

Nov 01 2023

Oct 01 2023

Oct 01 2023

Sep 01 2023

Sep 01 2023

Aug 01 2023

Aug 01 2023

Jul 01 2023

Jul 01 2023

Jun 01 2023

Jun 01 2023